Computerized Frame Measurement (CM) is a revolutionary technology transforming the automotive industry, especially for hybrid and electric vehicles (EVs). It offers precise evaluation of vehicle frames, enabling swift identification of structural issues in collision repair centers. CM optimizes the repair process, enhances quality, and ensures tailored solutions preserving original integrity. This advanced system streamlines production stages, from design to painting, and is crucial for maintaining EV performance and reliability due to their complex designs and lightweight materials. It provides unprecedented precision and efficiency over manual methods, reducing turnaround time, costs, and improving resale value through meticulous damage assessment and paintless repair techniques.

Computerized frame measurement (CFM) is transforming the automotive industry, especially for hybrid and electric vehicles (EVs). This advanced technology offers precise, digital assessments of vehicle frames, revolutionizing manufacturing processes. By eliminating manual measuring, CFM boosts efficiency and accuracy, crucial for these complex models with intricate designs. In this article, we explore the benefits of CFM, its integral role in EV and hybrid production, and how it’s navigating the future of automotive manufacturing.

- Understanding Computerized Frame Measurement: A Brief Overview

- The Role of CM in Hybrid and Electric Vehicle (EV) Manufacturing

- Implementation and Benefits: Enhancing Precision and Efficiency

Understanding Computerized Frame Measurement: A Brief Overview

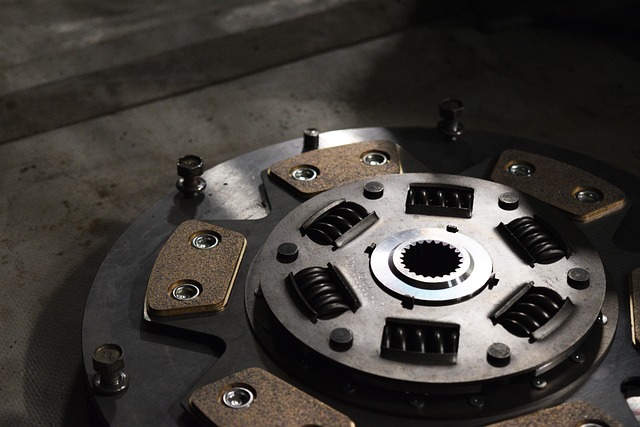

Computerized frame measurement is a cutting-edge technology transforming the automotive industry, especially for hybrid and electric vehicle (EV) models. This innovative process involves using advanced software and sensors to accurately assess and record the condition of a vehicle’s frame, providing detailed data on any damage or deformities. It’s a significant step forward from traditional manual measurements, offering increased precision and efficiency in various automotive services, including car body restoration and collision repair.

In a collision repair center or auto body shop, computerized frame measurement becomes an invaluable tool. By quickly and accurately identifying structural damage, technicians can develop effective repair strategies, ensuring the safety and integrity of hybrid and EV models. This technology not only streamlines the repair process but also helps maintain the vehicle’s original structure and performance, enhancing the overall quality of auto body services provided.

The Role of CM in Hybrid and Electric Vehicle (EV) Manufacturing

Computerized frame measurement (CM) plays a pivotal role in the manufacturing process of hybrid and electric vehicles (EVs), ensuring precision and efficiency throughout each stage. Unlike traditional methods, CM offers an advanced level of accuracy when it comes to measuring vehicle frames, which is critical for these cutting-edge automobiles. With their complex designs and lightweight materials, hybrid and EV models demand meticulous attention to detail in frame construction, assembly, and repair—all tasks facilitated by CM technology.

This innovative approach streamlines various processes, from initial frame design to subsequent auto body painting, auto body restoration, and even auto detailing. By providing detailed measurements and real-time data, CM helps manufacturers adhere to stringent quality standards, ultimately contributing to the overall performance and reliability of hybrid and EV models. This is particularly important as these vehicles continue to gain popularity for their environmental benefits and advanced engineering.

Implementation and Benefits: Enhancing Precision and Efficiency

Computerized frame measurement systems have revolutionized auto frame repair and automotive repair processes for hybrid and electric vehicle (EV) models. These advanced tools offer a significant leap in precision and efficiency compared to traditional manual methods. By employing sophisticated sensors and software algorithms, computerized frame measurement ensures accurate assessments of vehicle damage, particularly crucial for the intricate frames of modern EVs with their complex design and lightweight materials.

The benefits are manifold: faster turnaround times, reduced costs, and improved overall quality. This technology enables detailed 3D scanning of vehicle frames, allowing repair technicians to identify even subtle deformities. Moreover, it facilitates paintless dent repair techniques, preserving the original finish and enhancing the resale value of the vehicles. Computerized frame measurement systems are a game-changer in the industry, streamlining processes and setting new standards for excellence in auto frame repair and automotive repair services.

Computerized frame measurement (CFM) is revolutionizing hybrid and electric vehicle (EV) manufacturing. By offering enhanced precision and efficiency, CFM plays a pivotal role in ensuring these advanced vehicles meet stringent safety and performance standards. This technology not only streamlines production processes but also contributes to the overall quality and reliability of hybrid and EV models, paving the way for a more sustainable and efficient automotive industry.